Understanding the torque of a slewing bearing is crucial for those operating in industries that rely on heavy, load-bearing machinery. This component is integral to the smooth functionality and operational efficiency of equipment used in sectors such as construction, manufacturing, and renewable energy. Particularly, the slewing ring plays an essential role in handling the axial, radial, and moment loads that these pieces of machinery must endure, ensuring their capability to execute high-precision tasks.

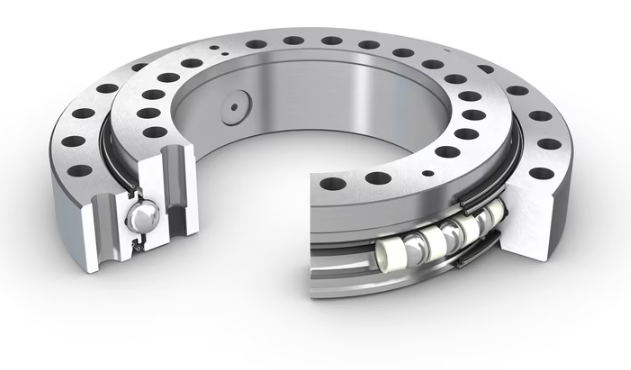

A slewing bearing, known in some contexts as a slewing ring, is a rotational rolling-element bearing that typically supports heavy but slow-turning or slow-oscillating loads. These complex bearings are an essential part of machines like cranes, excavators, and wind turbines. The torque of a slewing bearing refers to the rotational force necessary to turn the slewing ring, incorporating various factors such as friction, load, and the configuration of the gears integrated into the bearing.

Determining the specific torque of a slewing bearing involves a comprehensive understanding of the forces at play within the bearing mechanism itself. These include the friction between the rolling elements and raceways, the geometry of the bearing, the type and amount of lubrication used, and the nature of the loads being handled (whether they are constant, variable, static, or dynamic). Additionally, the preload of the slewing ring, which refers to the amount of force intentionally applied to the bearing to enhance its rigidity and handling characteristics, is also a determining factor in its torque.

The significance of the slewing bearing’s torque is evident when considering the operational demands of the machinery in which they are utilized. For instance, the precision and stability required in a medical CT scanner’s movements rely on the predictable and consistent torque of its slewing bearings. In contrast, the immense and fluctuating loads managed by a tower crane demand a slewing bearing capable of withstanding variable torques without a compromise in performance or safety.

It’s also noteworthy that improper handling of the torque in a slewing bearing can lead to operational hazards and machinery downtime. Excessive torque can cause wear and deformation, significantly reducing the operational life of the bearing. Conversely, insufficient torque may lead to insufficient bearing preload, resulting in poor performance and potential failure. Therefore, regular maintenance, including inspection and lubrication, is necessary to maintain the optimal performance and longevity of the slewing ring.

In the realm of industrial machinery and equipment, the slewing bearing represents a pinnacle of engineering necessary for the movement and functionality of various heavy-duty applications. The torque of a slewing bearing, hence, is not merely a representation of force but an indicator of the intricate balance required to maintain efficiency, safety, and precision in tasks that these monumental machines perform. Understanding this component’s functionality and significance can lead to better operational protocols, enhanced performance, and ultimately, extended equipment lifespans.